UK’s Biggest Steel Manufacturer Demonstrates Best Practice in Water Supply Resilience

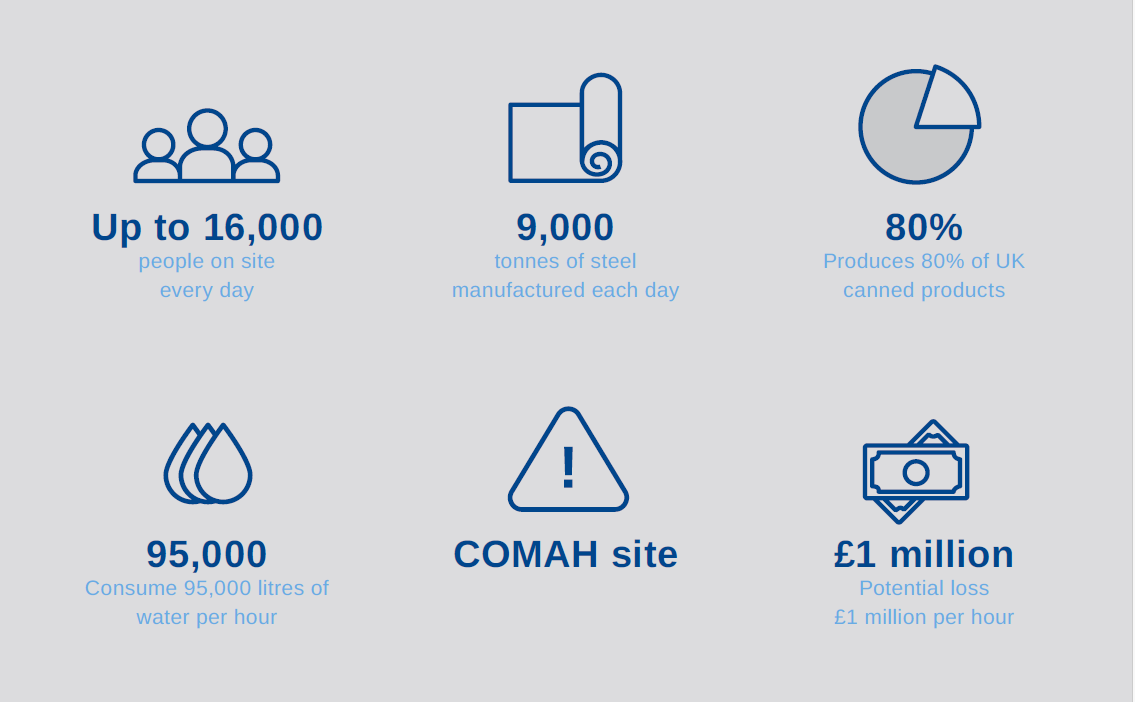

Our client is one of the world’s leading steel producers, and the largest primary steelmaking company in the UK, operating 24 hours a day, seven days a week. Its three manufacturing sites in South Wales employ 4,000 people, with the potential for an additional 12,000 contractors on site every day. The sites produce almost 9,000 tonnes of steel every day, which is used in everything from cars and construction to food safe packaging, cans and tins, providing a vital foundation for many of the UK and Europe’s strategic supply chains.

Understanding the risk

At these locations, three continuous casters take molten steel and cast it into strands which are cut into red-hot solid bars of steel, each weighing around 30 tonnes. To enable this process, a reliable supply of 95,000 litres of water per hour is required, including water for dust control, cooling, descaling and other processes. In addition, a further four litres are required daily, per person for welfare, drinking and washing.

Even though the company had yet to experience water outages at the sites, it realised the importance of commissioning a site-specific emergency plan for water, to protect equipment, personnel, productivity, revenue, and reputation, and came to Water Direct to help.

The company’s Energy Category Manager explains the complex nature of day-to-day operations at the Port Talbot manufacturing site:

“The potential for chemical spills and splashes means that a constant and reliable water facility is crucial for keeping employees safe during daily operations. A sudden interruption would be a disaster. The risk could be loss of life, or it could be millions of pounds. We are operating on one of the most dangerous sites in the UK. If you stop one of the operations you can lose a million pounds an hour. If it’s a complete stop and our blast furnace comes down it would take 15-30 days to come back online.”

Protecting core operations

Core operations take place at Port Talbot, which, as a site subject to (Control of Major Accident Hazards (COMAH) Regulations 2015, is one of the company’s most high-risk sites. Thousands of companies across a variety of industries rely on the steelmaker to provide half a million tonnes of steel within a two-week lead time, and water is essential to its operations.

This led the company to work with Water Direct’s specialist business continuity and planning team to complete a comprehensive site audit and risk analysis together with a robust water contingency plan that covered operational and human risk.

Research shows that up to two-thirds of UK businesses have no contingency plan in place for loss of water supply

Water utility companies aim to provide businesses with water 24 hours a day, 365 days a year. However, in the event of a water supply interruption, water companies are not obligated to immediately restore service. Businesses can be left without water supply for hours, days, or even weeks, causing complete shutdowns for most operations.

Recognising the critical importance of a reliable water supply to their operations, the company understood the urgency of having a detailed contingency plan with an assured response. “The water supply contingency plan we designed with Water Direct gave us a great deal of insight,” says our client. “We thought we knew everything about our site, but the audit and planning process revealed potential hazards we hadn’t considered.”

Identifying these areas gave the company the confidence to take necessary steps toward planning for large-scale water supply interruptions. A clear action plan for introducing an alternative water supply was implemented, enabling the company to act rapidly to avoid disruption should their water supply unexpectedly stop.

A WaterTight response

As experts in planning for business continuity, Water Direct’s WaterTight team understood the critical importance of water to the company’s operations and the need for a robust contingency plan with a rapid, assured response. Chemical spills were not the only concern; any large-scale disruption to the water supply could result in financial losses of millions of pounds and cause significant damage to on-site machinery that relies on water to operate.

Our client explains further: “Due to the nature of our operations, on-site machinery requires a controlled, slow turn down; otherwise, it could lead to hazardous activities. This means even the bare minimum of water is essential for operations.” In addition to health and safety risks, the company had to consider the impact of halted productivity, unprotected equipment, and significant revenue losses. Following an on-site audit, the company received a site-specific plan, specially designed by our expert WaterTight team, to meet the unique needs of the site. This plan ensures a robust, assured response is in place to minimize disruption to operations.

Are your Business Continuity Plans WaterTight?

Every WaterTight contingency plan is specifically tailored to suit the needs and requirements of individual clients, and particularly the sites they operate from. Our client noted: “Our operations team reported that everything was brilliant, from the site visit and planning to interactions and follow ups and was impressed by the quality and content of the on-site report.”

He further encouraged other businesses to consider a water contingency plan stating: “A clean, uninterrupted water supply is critical, especially if it is needed for health and safety, which has a direct impact on employee wellbeing.”

The steel manufacturer recognises how crucial it is to have a reliable water supply and found that working through the audit and risk analysis process with the specialists at Water Direct enabled a detailed, tailored report enabled clear planning, even for areas of site that hadn’t previously been considered as a hazard risk.

Do you have a plan for loss of water supply? Could loss of water present hazards on site that you aren’t aware of? Could your employees be at risk? Taking action and having a reliable water emergency plan in place is essential; Water Direct developed its award-winning WaterTight service to help even the most complex businesses stay operational and mitigate any water supply issues.

Share: