Planning Temporary Water Supply for Construction Sites

A dependable temporary water supply is essential for any construction site. From welfare facilities and dust suppression to concrete batching and site cleaning, water keeps operations running safely and efficiently. Without a suitable supply in place, contractors risk delays, compliance issues and rising project costs.

This guide explains how to plan a temporary water supply for construction sites, what to consider before work begins, and how specialist alternative water suppliers like Water Direct support projects nationwide.

Why Construction Sites Need a Planned Water Supply

Construction projects often begin before a permanent mains connection is available. Even when connections exist, pressure limitations, local restrictions or site layout can make access difficult.

A planned temporary water supply supports:

- Welfare and sanitation facilities

- Dust suppression and wheel washing

- Concrete mixing and batching

- Site cleaning and equipment washing

- Drinking water for staff

- Fire safety and contingency planning

With multiple teams working on tight schedules, having the right water provision in place ensures operational continuity from day one.

Key Considerations When Planning Water for Construction Sites

1. Assess Your Site’s Water Demand

Before selecting equipment or delivery methods, calculate your expected water usage based on:

- Number of workers

- Welfare block requirements

- Concrete or mortar production

- Dust suppression frequency

- Any specialised equipment needing water

- Project duration and seasonal changes

A clear usage estimate prevents shortages and avoids unnecessary delivery costs.

2. Understand Your Site Layout

Review how the site will develop over time:

- Is there access for tankers?

- Are there safe delivery routes?

- Will storage tanks need to be moved later?

- Does the location require multiple filling points?

Early planning helps position tanks, bowsers and pipework correctly without disrupting operations later.

3. Choose the Right Temporary Water Storage

Construction sites commonly use a combination of:

- Static water tanks (1,100–10,000 litres)

- Towable bowsers (around 2,000 litres)

- Bulk storage solutions such as Aqubes

These provide the flexibility to support welfare units, standpipes, or ongoing site works. A reputable alternative water supplier will also ensure all tanks are clean, disinfected and fully compliant before delivery.

4. Decide How Water Will Be Delivered

You may choose:

Bulk Tanker Deliveries

Potable water tankers (19,000L or 30,000L):

- Suitable for larger sites

- Fill static tanks and bowsers

- Ideal for initial setup and regular replenishment

On-Demand Top-Ups

Scheduled or call-off deliveries enable sites to manage consumption peaks.

Direct Mains Support (Where Allowed)

Some projects require direct injection into temporary networks, carried out under strict quality assurance procedures.

5. Ensure Water Quality & Compliance

All water provided for welfare, drinking, and washing must be:

- Potable

- Fully traceable

- Tested and compliant with UK standards

- Delivered in disinfected, sealed tanks

Construction sites must also follow water safety procedures, such as regular flushing and approved chlorination, when connecting temporary systems to permanent pipework.

6. Build a Contingency Plan

Construction is highly dependent on reliable water access. Unplanned outages can halt work entirely.

A strong contingency plan should include:

- Alternative delivery options

- Back-up storage tanks

- Emergency tanker mobilisation

- Access routes for 24/7 response

- Guaranteed supply arrangements through a dedicated contingency contract, such as Water Direct’s WaterTight

This ensures operations remain resilient throughout the project.

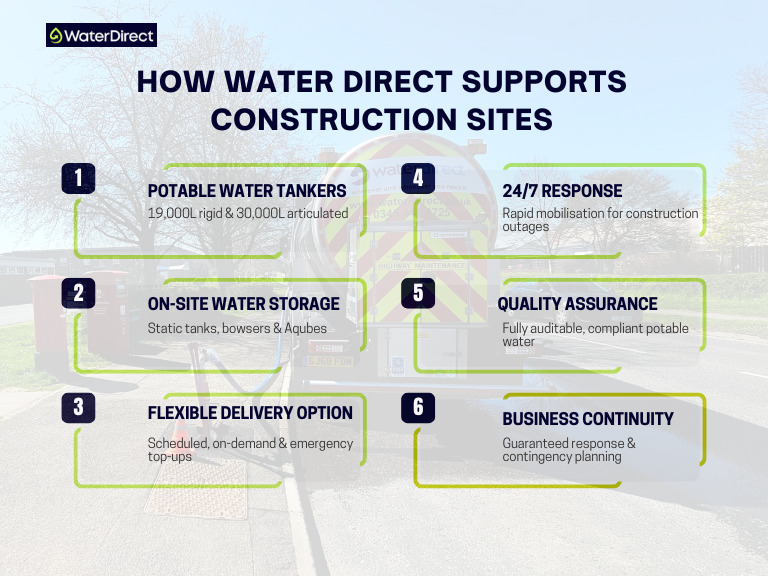

How Water Direct Supports Construction Sites

Water Direct provides complete temporary water solutions for construction and civil engineering projects across the UK.

Services include:

- Potable water tankers (rigid and articulated)

- Static tanks, bowsers and Aqubes

- Scheduled, on-demand and emergency deliveries

- UK-wide 24/7 emergency response

- Fully auditable quality management

- Business continuity planning / WaterTight contracts

With rapid mobilisation and national coverage, Water Direct ensures construction sites remain operational, compliant and resilient at every stage.

Conclusion

Planning a temporary water supply is essential for keeping construction projects on schedule. By understanding your water demand, storage needs, and delivery options, and partnering with a specialist alternative water supplier, you ensure safe, compliant, and reliable water throughout the entire build.

FAQs

Why do construction sites need a temporary water system?

Construction sites need a temporary water system to keep welfare units running, support concrete batching, manage dust, maintain hygiene and ensure operational continuity. Without planned water provision, projects can face delays and compliance issues.

How is water delivered to construction sites?

Water is typically delivered by potable water tankers, which fill onsite tanks and bowsers. Deliveries can be scheduled, on-demand, or provided as an emergency response if the site loses access to its usual supply.

Is potable water required for construction sites?

Yes. Any water used for welfare facilities, handwashing, cleaning, drinking or food preparation must be fully potable, compliant and traceable. Only approved suppliers should provide water for these uses.

What happens if a construction site loses its water supply?

If a site loses its water supply, an emergency water supplier can deploy potable tankers, bowsers or bottled water to restore operations quickly. A contingency plan ensures faster response and minimises downtime.

Share: